10kw 12kw Laser Cutting Machine for Metal Sheet

10kw 12kw Laser Cutting Machine for Metal Sheet

Thu Oct 12, 2023 10:39 pm

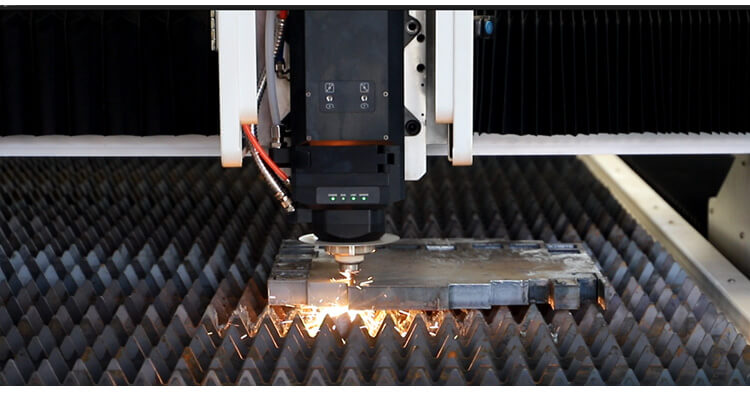

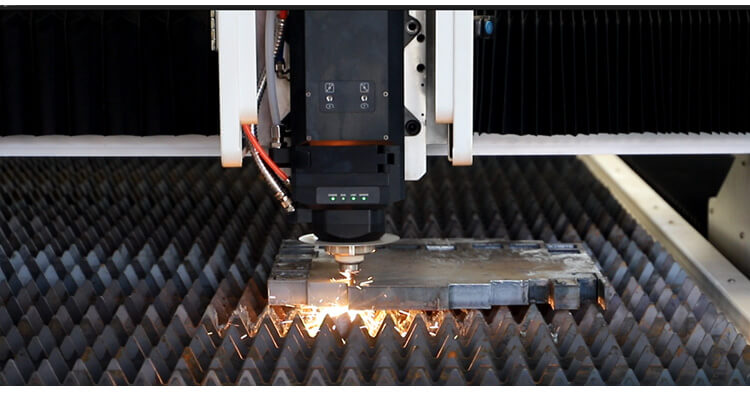

High Power Laser Sheet Cutting Machine “ultra-large format” refers to the machine’s ability to handle large sheets of material, with a maximum length of up to 32m and a width of up to 5m. It is commonly used in industries such as aerospace, steel structure, and construction, where precision cutting of large parts is required. It allows for faster and more precise cutting, making it a popular choice for industrial applications.

Large Format Laser Cutting MachineSheet metal laser cutting machine is a type of computer-controlled machine that uses a high-powered laser beam to cut and engrave metal materials. Laser cutting machines are capable of cutting a wide range of metals, including steel, aluminum, brass, and copper, with a high degree of precision and speed.

Completely controlled by CNC, fiber laser metal cutting machine can produce complex parts with high tolerance repeatedly and consistently. Laser cutting can also produce high quality cut edges, usually without further cleaning, processing or finishing, thus reducing the need for secondary processing.

The higher power output of a 12000w laser cutting machine allows it to cut through thicker materials more quickly than lower-powered machines. This can significantly increase productivity and reduce production times for large-scale cutting operations.

A high-power laser cutting machine is a specialized type of laser cutting equipment that utilizes a powerful laser beam to cut through thick and dense materials with speed and precision. These machines are designed to handle heavy-duty cutting applications that require increased power and capability compared to standard laser cutting machines.

Ultra high power laser cutting machine, 10KW,12KW, 15KW, 20KW,30KW available

A laser cutting machine for metal is a powerful tool used in industrial manufacturing processes to cut and shape various types of metal materials with the precision and speed of a laser beam. Laser cutting offers several advantages over traditional mechanical cutting methods, such as increased accuracy, faster production times, and the ability to cut intricate and complex designs.

Features and benefits of laser cutting machines for metal:

Precision and Accuracy: Laser cutting machines utilize a focused and concentrated laser beam to achieve extremely precise and accurate cuts. They can achieve high levels of detail, intricate patterns, and fine contours, making them suitable for applications where precision is crucial.

Versatility: Laser cutting machines can work with a wide range of metal materials, including stainless steel, carbon steel, aluminum, copper, brass, and more. They are capable of cutting varying thicknesses, from thin sheets to thicker plates.

Non-Contact Cutting: Laser cutting is a non-contact process, meaning the laser beam does not physically touch the material being cut. This eliminates the risk of damage or distortion to the workpiece and allows for cleaner and smoother cuts.

Speed and Efficiency: Laser cutting machines can perform cuts at high speeds, significantly reducing production time compared to traditional cutting methods. They offer rapid piercing capabilities and continuous cutting without the need for tool changes.

Minimal Material Wastage: Laser cutting minimizes material wastage due to its narrow kerf width. The precise laser beam enables efficient nesting of parts, optimizing material usage and reducing costs.

Complex and Intricate Designs: Laser cutting machines excel at cutting intricate and complex designs, including sharp corners, small holes, and fine details. They can also perform 3D laser cutting, allowing for bevel cuts and multi-dimensional shapes.

Automation and Integration: Laser cutting machines can be integrated into automated systems, enabling efficient and continuous production. They can be programmed to follow CAD designs and can work in conjunction with other machinery or robotic systems.

Minimal Post-Processing: Laser-cut metal parts often require minimal post-processing, such as deburring or finishing, due to the clean and precise cuts achieved by the laser beam. This reduces the overall production time and cost.

Large Format Laser Cutting MachineSheet metal laser cutting machine is a type of computer-controlled machine that uses a high-powered laser beam to cut and engrave metal materials. Laser cutting machines are capable of cutting a wide range of metals, including steel, aluminum, brass, and copper, with a high degree of precision and speed.

Completely controlled by CNC, fiber laser metal cutting machine can produce complex parts with high tolerance repeatedly and consistently. Laser cutting can also produce high quality cut edges, usually without further cleaning, processing or finishing, thus reducing the need for secondary processing.

The higher power output of a 12000w laser cutting machine allows it to cut through thicker materials more quickly than lower-powered machines. This can significantly increase productivity and reduce production times for large-scale cutting operations.

A high-power laser cutting machine is a specialized type of laser cutting equipment that utilizes a powerful laser beam to cut through thick and dense materials with speed and precision. These machines are designed to handle heavy-duty cutting applications that require increased power and capability compared to standard laser cutting machines.

Ultra high power laser cutting machine, 10KW,12KW, 15KW, 20KW,30KW available

A laser cutting machine for metal is a powerful tool used in industrial manufacturing processes to cut and shape various types of metal materials with the precision and speed of a laser beam. Laser cutting offers several advantages over traditional mechanical cutting methods, such as increased accuracy, faster production times, and the ability to cut intricate and complex designs.

Features and benefits of laser cutting machines for metal:

Precision and Accuracy: Laser cutting machines utilize a focused and concentrated laser beam to achieve extremely precise and accurate cuts. They can achieve high levels of detail, intricate patterns, and fine contours, making them suitable for applications where precision is crucial.

Versatility: Laser cutting machines can work with a wide range of metal materials, including stainless steel, carbon steel, aluminum, copper, brass, and more. They are capable of cutting varying thicknesses, from thin sheets to thicker plates.

Non-Contact Cutting: Laser cutting is a non-contact process, meaning the laser beam does not physically touch the material being cut. This eliminates the risk of damage or distortion to the workpiece and allows for cleaner and smoother cuts.

Speed and Efficiency: Laser cutting machines can perform cuts at high speeds, significantly reducing production time compared to traditional cutting methods. They offer rapid piercing capabilities and continuous cutting without the need for tool changes.

Minimal Material Wastage: Laser cutting minimizes material wastage due to its narrow kerf width. The precise laser beam enables efficient nesting of parts, optimizing material usage and reducing costs.

Complex and Intricate Designs: Laser cutting machines excel at cutting intricate and complex designs, including sharp corners, small holes, and fine details. They can also perform 3D laser cutting, allowing for bevel cuts and multi-dimensional shapes.

Automation and Integration: Laser cutting machines can be integrated into automated systems, enabling efficient and continuous production. They can be programmed to follow CAD designs and can work in conjunction with other machinery or robotic systems.

Minimal Post-Processing: Laser-cut metal parts often require minimal post-processing, such as deburring or finishing, due to the clean and precise cuts achieved by the laser beam. This reduces the overall production time and cost.

Permissions in this forum:

You cannot reply to topics in this forum